iCOOL Cooling Systems

|  |

|  |

|  |

Cooling systems

TIAM Network, a company specializing in providing IT solutions for cooling solutions and the first manufacturer of modern data center cooling systems in Iran (In-Rack, Side Air Flow, In-Row, In-Room Cooling System), with the production of efficient cooling systems, Low-cost products and products that do not damage the environment, in fact, provide solutions that are adaptable, reliable and in accordance with the needs of customers. The easy installation and implementation and extensive after-sales service of these systems is one of the benefits of this suite.

The cooling products of the company's data center are manufactured with the iCOOL brand.

The stages of production and delivery of cooling systems are as follows:

Design and Engineering

• Use of the latest numerical solution and analysis of CFD (Computational Fluid Dynamics) in modeling and designing the thermal and cooling data center

• The use of the latest and most efficient cooling and ventilation software for the design of cooling systems

• Use of various tests to analyze the operation of the cooling system

• Analyze, review and consult with a cost-cutting approach and increase energy efficiency

• Design, test and manufacture of all cooling products by Iranian specialist experts in this company

• Use the expertise and experience of Johnson Controls Canada engineers

Services

- Sales of cooling equipment across Iran

- Implementation of data center cooling systems

- Support of data center cooling systems

- Supply of cooling system parts

- Wide after sales services

- Equipped with a specialized laboratory for testing data center cooling systems

Cooling Solutions

Considering the 24-hour operation of IT thermal equipment in the data center, it is recommended that, in order to provide the required cooling, a clear solution for the distribution of cold air and hot air should be considered in order to provide the required cooling, while matching the hot and cold air flow paths.

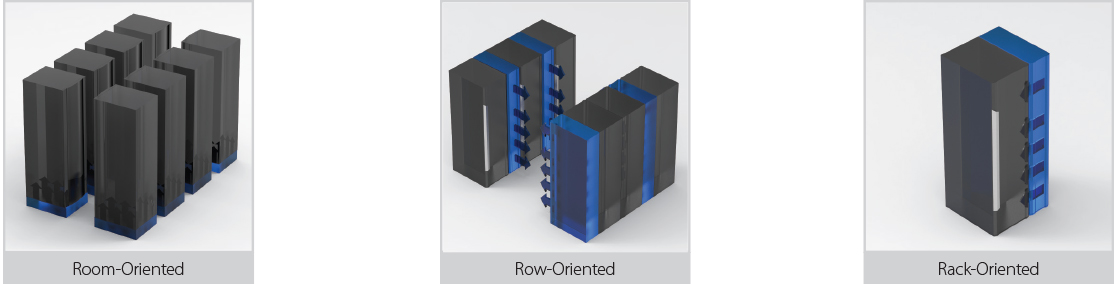

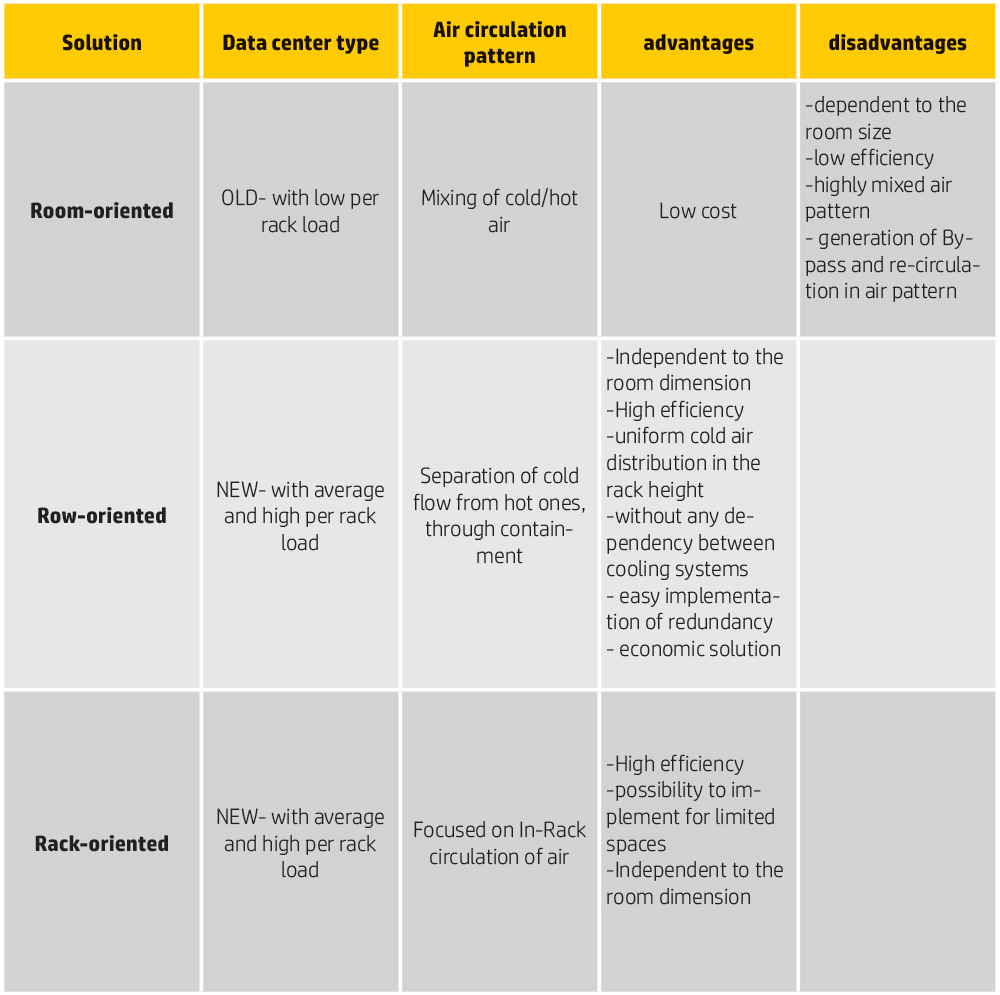

In general, the following three methods are used to control the temperature in a data center:

• Room-Oriented

• Row-Oriented

• Rack-Oriented

The main function of the cooling system is to produce cold and distribute it for the use of equipment. In the first part (cold production), all three solutions are similar. In other words, the amount of cold that they produce is equal to the amount of heat generated in the room by the equipment. In the second part (distribution of produced cold air), each of the three solutions has unique methods for distributing cold weather. In the screenshots below you can see the differences between the three solutions:

The first data center cooling solution is Room-Oriented. In this solution CRAC unit or Computer Room Air Conditioner is assigned to the entire room. In a rows-based approach, the CRAC unit is assigned to each row, and in the Rack-Oriented solution, the CRAC unit is assigned to each rack. The comparison of three cooling solutions is presented in the following table

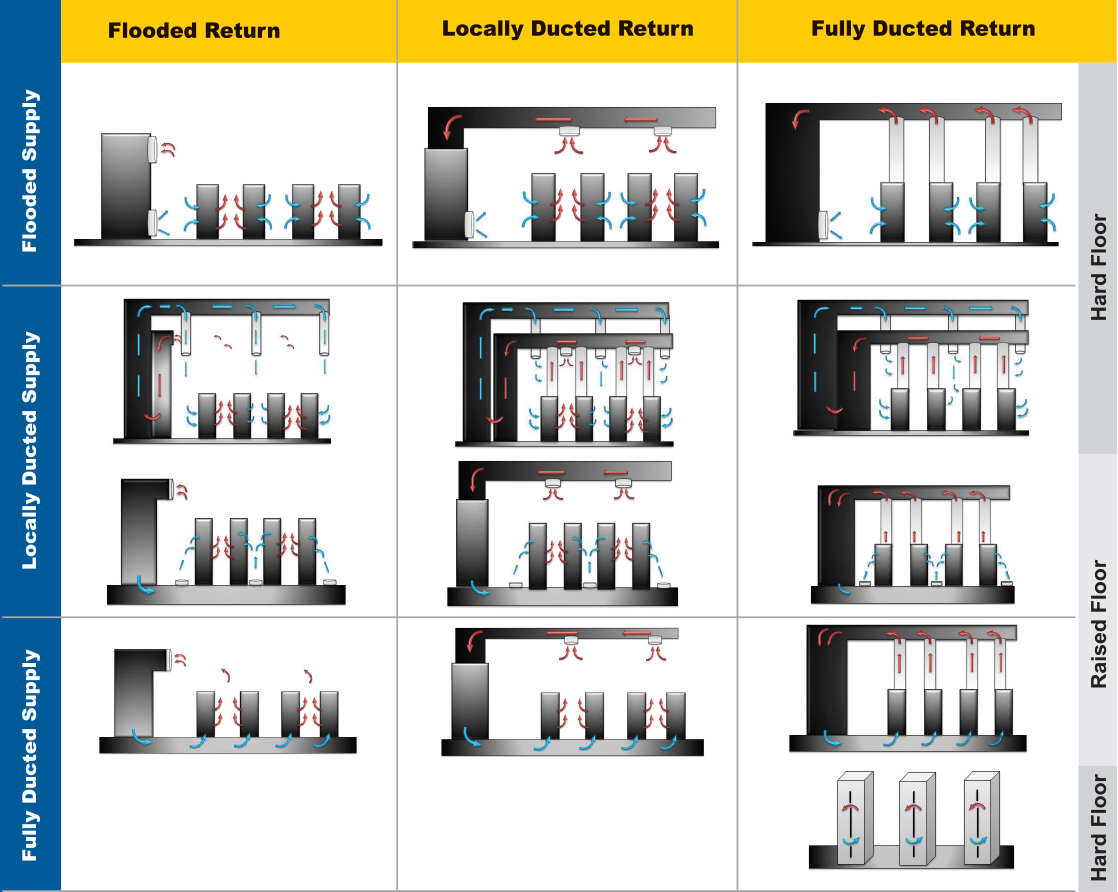

Distribution methods

The cooling system mechanisms in the high-capacity data center should be based on distribution and collection. For each mechanism, there are three main methods:

Non-centralized (flooded)

In the Flooded solution, the distribution or collection system distributes or collects air flow without any specific doct.

Semi-centralized (Locally Ducted)

In a locally-ducted solution, depend on the distribution or recirculation system, airflow is distributed or collected through a duct near a cold or hot channel.

Focused (Fully Ducted)

In Fully Ducted method, the distribution and collection system distributes or collects air directly through a closed path from a hot or cold corridor.

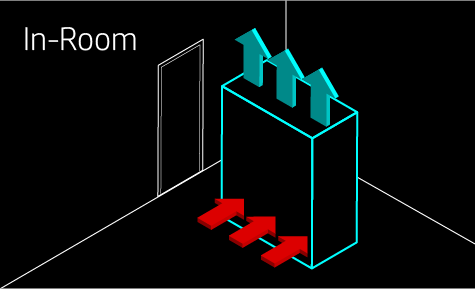

TIAM Network uses two types of cooling technology, depending on the customer's needs: In-Room, In-Rack, In-Row, Side Air Flow.

• Direct Expansion

• Chilled Water System

Direct Expansion

This technology, which is renowned for home appliance cooling, uses a refrigerant fluid as a heat transfer medium to absorb internal heat and transfer it to the external environment. The internal unit of the DX system consists of a pressure reduction mechanism and a heat exchanger called the Evaporator. In the pressure reduction mechanism, the pressure of liquid refrigerant drops and the liquid is ready to evaporate. Then the low pressure fluid enters the evaporator and, by absorbing the internal heat, converted to the gas during the evaporation heat recovery process. After this stage, the refrigerant gas is transferred to the external unit.

The external unit consists of a compressor and a heat exchanger called a condenser. The refrigerant gas is initially introduced into the compressor and its pressure is greatly increased and is ready to be condensed. Then the high-pressure gas enters to the condenser Exchanger and converts to the liquid by transferring the heat to the external medium in the process, and then returns to the internal unit.

In this system, the refrigerant gas is circulated repeatedly and the refrigerant gas absorbs the heat in the interior and transmits it to the external environment. Due to the fact that the expansion of the refrigerant is a direct process and it is necessary that the refrigerant passes through the entire path between the external and internal units, there is a limitation of the length for the path. In this system, the maximum vertical distance between the indoor unit and the external unit is 15 meters and the maximum horizontal distance between these two units is 25 meters.

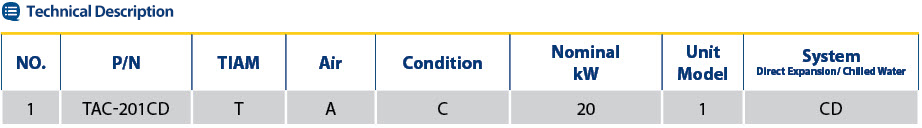

External DX unit with a capacity of 5 tons of refrigeration

• Suitable for all In-Rack, In-Row, Side Air Flow and In-Room systems with a capacity of 5 tons of refrigeration

• Nominal power: 20 kW

• Fan: Two 700-watt fan axial devices

• Fan distance: 1350 rpm

• Compressor type: Three-phase Scroll

• Compressor current consumption: 10 A three-phase

• Electric power consumption: 6000 watts

• Equipped with Fan Cycle Switch

• Control the condition of the condenser fan to eliminate forced heat transfer in cold seasons

• Equipped with high & low pressure compressor

• Compressor protection at gas pressure, high output and low input

• Equipped with Solenoid Electronic valve

• Gas pressure control system for balancing gas pressure during system shutdown

Chilled Water System

In this system, the refrigerant circuit in the DX system cools the water instead of directly cooling the air inside the interior of the air, and then cold water is sent by a pump to the internal units. This cold water transmits heat in a heat exchanger with ambient air and cools the air.

In this process, the air temperature is reduced and the temperature of the cold water rises and the water is heated.

The hot water then returns to the tubular tube converter and the hot water cools down during the heat transfer with the refrigerant.

In this system, it is possible to use the pump by defining the material of the cooling interface (water), and the limitation of the length difference between the unit and the external unit is lost.

External Unit (Chiller)

• Suitable for all In-Rack, In-Row, Side Air Flow and In-Room systems with various capacities.

• Nominal Capacity: Corresponds to the total capacity of internal units