Power Distribution Units

|  |

|  |

|  |

Power Distribution Unit

Today, electric power has affected all aspects of human life. In addition to home-use, in industrial centers, the distribution of electricity, maintaining the health and safety of devices connected to power distribution panels is a major concern for consumers.

And preventing power outages and creating electrical fluctuations, in the distribution paths and the proper discharge of excess electricity, is one of the most important needs of these users.

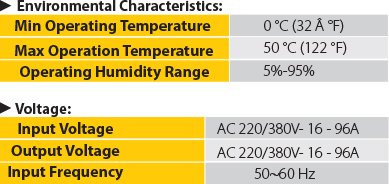

Due to the size of the installed electrical equipment on the racks and the importance of supplying the power to these equipment, TIAM Networks, in order to meet the needs of users, with the Power Distribution Unit (iPOWER) Designed and presented in a variety of ways, in accordance with the latest national and international standards and codes.

In order to protect the equipment and discharging excessive electrical loads, in accordance with the standard in the sockets, insulated copper insulators, power cords and main PDUs for connection to the system are considered. Due to the specific design, the features that are considered in these products are used in computer centers, telecommunications and audio and at home.

The aluminum profile frames in iPOWER's modular PDUs are designed to fit other plastic components (ABS) into sliding doors.

Using this solution is a great help in the beauty, simplicity, ease of repair, and flexibility in creating different layouts of sockets, switches, fuses, and voltage protection equipment.

Rotating brackets in the iPOWER PDUs that are modular ducts allow the product to be installed on the wall, in addition to being mounted on the front and rear rails.

Also, if you change the bracket's position, it's possible to install brackets in the space without occupying the appropriate Zero Unit.

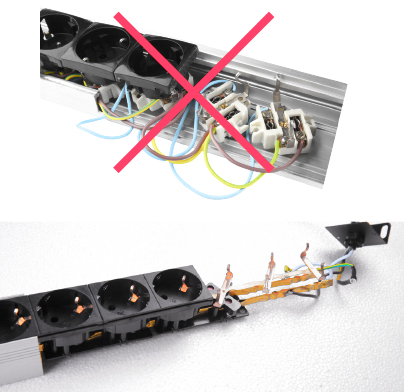

In order to reduce the electrical hazards in designing and manufacturing all iPOWER modular PDUs, from the beginning, removing the wiring and replacing it with copper chip in plastic insulation, the complete connection of the plug to the insulated copper shaker is provided.

In some instances in the market, due to the need to use three separate cable sections in each outlet, in the production of a 9-port power distribution panel, there are more than 50 electrical contact points.

In the design of the TPD-10X models, iPOWER PDUs, which are two modular branches, use insulating copper pins, and the risk of this risk is reduced to 6, which is controlled by a special design and engineering.

Also, if you do not use insulated copper chips, inside these panels, there is a need to pass through several strands of hazardous cables, below the sockets.

In the latest strategy, the risks in this section are also eliminated.

In the design and layout of the sockets, iPOWER's modular PDUs are designed for each 40 x 43 mm socket. Power distribution Units are designed according to European standards and with an engineering perspective.

In the design and layout of the sockets, iPOWER's modular PDUs are designed for each 40 x 43 mm socket. Power distribution Units are designed according to European standards and with an engineering perspective.

The measurements and calculations are designed to allocate the minimum vertical space to the power distribution panel, in addition to using the maximum horizontal space for deploying the largest number of sockets per row.

In other words, due to the 19-inch margin, the rails for installing PDUs at the rack, it is necessary to have a maximum horizontal dimension of 19 inches. In this way, a maximum of 9 sockets will be provided.

On the other hand, in order to optimize the vertical space of the rack, the plugs must be arranged angularly in the sockets so that, in addition to maintaining the independence and function of each plug, the least space is occupied by the plugs, and all 9 sockets are only in less than An unity unit without the occupancy of the peripheral space of the PDU can be used.

In order to control the power and increase the electrical safety of the iPOWER power distribution panels, the frame of all sockets with a variety of control and protection systems, such as the switch and power supply switch, power protection device, glass fuse, 16 and 32 amp miniature fuses, etc can be replaced.

In the new generation of these products, copper wires have been used inside the insulation in order to increase the safety coefficient and create a suitable substrate for high current flows, and the complete resistance to the heat generated by this flow. In iPOWER modular PDUs.

In the production of iPOWER PDUs, it has been attempted to use different combinations of common sockets in the IT industry, given the varying needs of low-consumption and high-consumption consumers.

The iPOWER PDUs have a minimum of 6 and a maximum of 40 sockets in the following models with a maximum transmittance total output of 96 (32 × 32):

- Simple dins DIN49440

- IEC 60320 / C-13 Sockets Back to Back

- IEC 60320 / C-19 sockets back to back

The iRACK rack design and iPOWER PDUs provide this feature to its users, which allows the installation of iPOWER PDUs (except for TPD-916M models) within the columns of all iRACK stacks (other than the Eco rack), simply Have.

This allows them to be installed as a Zero Unit on the rack, and will not be occupied because of the special design of the column rack, even the space inside the rack.

|  |

In the design and production of iPOWER PDUs, the needs of high-end users and professional users in the data center, safe rooms and critical centers are considered.

TIAM Networks, in order to ease the monitoring, control the voltage and ampere consumption, and to establish remote control of the power consumption of each device, using the latest technology in the world, a variety of Power Distribution Units equipped with Amperemeter and Voltmeter, IP Metered Switched, and ATS PDU voltmeters with networked capability.